The term “how to make chloroform” generally refers to the process of synthesizing chloroform, a colorless, volatile liquid with a characteristic sweet odor and a slightly burning taste.

Historically, chloroform has been used for various purposes, including as an anesthetic, an antiseptic, and an industrial solvent. However, due to its potential toxicity, it is no longer commonly used in medical settings and its industrial applications have been largely replaced by safer alternatives.

Given the hazardous nature of chloroform and the strict regulations surrounding its production, attempting to synthesize it without proper training, facilities, and safety measures is strongly discouraged. It is important to remember that the safe handling and disposal of chloroform require specialized knowledge and equipment.

how to make chloroform

Understanding the various aspects of chloroform synthesis is crucial due to its historical significance and potential implications.

- Definition: Chloroform is a colorless, volatile liquid with a characteristic sweet odor and a slightly burning taste.

- Synthesis: Chloroform can be synthesized through various methods, including the reaction of chlorine and methane in the presence of a catalyst.

- Properties: It is denser than water and sparingly soluble in it. It is also highly flammable and has anesthetic and antiseptic properties.

- Usage: Historically, chloroform was used as an anesthetic in surgery and as an antiseptic in medical settings. It has also been used in the production of dyes, rubber, and other industrial applications.

- Toxicity: Chloroform is a toxic substance and exposure to high concentrations can cause dizziness, nausea, and even death. It can also cause liver and kidney damage upon prolonged exposure.

- Regulation: Due to its toxic nature, the production, sale, and use of chloroform are strictly regulated in many countries.

These aspects highlight the importance of understanding the properties, synthesis, and risks associated with chloroform. Its historical use as an anesthetic and antiseptic demonstrates its significance in the medical field, while its toxicity and strict regulations underscore the need for careful handling and controlled use.

Definition

This definition provides a concise description of chloroform’s physical properties, setting the foundation for understanding its chemical nature and potential uses.

-

Chemical Composition and Structure

Chloroform, with the chemical formula CHCl3, is a halogenated hydrocarbon composed of one carbon atom, one hydrogen atom, and three chlorine atoms. Its molecular structure is characterized by a tetrahedral shape, with the carbon atom at the center and the chlorine atoms occupying the four corners. -

Characteristic Odor and Taste

Chloroform’s distinct sweet odor and slightly burning taste are attributed to its volatile nature and the presence of chlorine atoms. The sweet odor is often described as resembling that of ether, while the burning taste arises from its interaction with the mucous membranes in the mouth and throat. -

Physical Properties

Chloroform is a colorless, volatile liquid that is denser than water and sparingly soluble in it. Its low boiling point of 61.2 C (142.2 F) contributes to its high volatility, allowing it to evaporate readily at room temperature.

Understanding these properties is essential for handling, storing, and utilizing chloroform safely and effectively. Its distinct odor and taste serve as important sensory cues for detecting its presence, while its physical properties influence its behavior in various chemical reactions and applications.

Synthesis

The synthesis of chloroform involves specific chemical reactions and processes, which are key to understanding “how to make chloroform”. One common method is the reaction between chlorine and methane in the presence of a catalyst. This process highlights several important facets:

-

Reaction Mechanism

The reaction between chlorine and methane proceeds via a free radical chain mechanism. Chlorine atoms, generated by the catalyst, react with methane molecules to form methyl radicals. These methyl radicals then react with chlorine molecules to form chloroform and hydrogen chloride.

-

Catalyst

The catalyst plays a crucial role in the reaction by facilitating the generation of chlorine atoms. Common catalysts used include iron(III) chloride (FeCl3) and ultraviolet light.

-

Reaction Conditions

The reaction is typically carried out at elevated temperatures and pressures to increase the rate of reaction and yield of chloroform.

-

Byproducts

In addition to chloroform, the reaction also produces hydrogen chloride gas as a byproduct. This byproduct needs to be removed or neutralized to obtain pure chloroform.

Understanding these facets provides a deeper insight into the synthesis of chloroform, enabling better control and optimization of the process. It also highlights the importance of proper safety measures and specialized equipment when working with hazardous chemicals like chlorine and chloroform.

Properties

The properties of chloroform play a crucial role in understanding “how to make chloroform” and its subsequent applications. Its density, solubility, flammability, anesthetic, and antiseptic properties are all interconnected and influence the synthesis, handling, and use of chloroform.

The fact that chloroform is denser than water and sparingly soluble in it affects its separation and purification during synthesis. Its higher density allows it to be separated from water by decantation or distillation. However, its low solubility in water limits its use in aqueous solutions or biological systems.

The high flammability of chloroform is a significant safety concern. Its vapors can easily ignite, forming toxic gases, which necessitates proper ventilation and strict adherence to safety protocols during synthesis and handling.

Chloroform’s anesthetic and antiseptic properties were historically significant, leading to its use in surgery and medical procedures. Its ability to induce unconsciousness and relieve pain made it a valuable anesthetic. Additionally, its antiseptic properties were useful for sterilizing medical instruments and surfaces.

Understanding these properties is essential for the safe and effective synthesis, handling, and application of chloroform. It guides the choice of appropriate reaction conditions, separation methods, safety measures, and storage protocols.

Usage

The usage of chloroform is closely intertwined with “how to make chloroform” as it influences the synthesis methods, purification techniques, and safety protocols employed. Understanding the historical and industrial applications of chloroform provides valuable insights into its properties and the reasons behind specific synthesis procedures.

For instance, the medical applications of chloroform as an anesthetic and antiseptic drove the development of efficient synthesis methods that ensured high purity and consistency. The need for large-scale production for industrial applications, such as dye manufacturing and rubber production, further necessitated the optimization of synthesis processes to increase yield and efficiency.

Additionally, the understanding of chloroform’s properties, such as its flammability and toxicity, guided the development of appropriate safety measures during synthesis and handling. The knowledge of its solubility and volatility influenced the choice of extraction and purification techniques.

In summary, the usage of chloroform in various fields has shaped the development of synthesis methods, purification techniques, and safety protocols associated with “how to make chloroform.” Understanding the historical and industrial applications provides a comprehensive perspective on the synthesis and handling of this compound.

Toxicity

The toxicity of chloroform is an essential factor to consider when discussing “how to make chloroform.” Understanding the potential hazards associated with chloroform helps ensure appropriate safety measures are taken during its synthesis, handling, and disposal.

-

Acute Toxicity

Exposure to high concentrations of chloroform can lead to acute toxicity. Inhalation of chloroform vapors can cause dizziness, nausea, vomiting, and even death due to its depressant effects on the central nervous system.

-

Chronic Toxicity

Prolonged exposure to lower concentrations of chloroform can result in chronic toxicity. It can cause damage to the liver and kidneys, leading to impaired function and potential organ failure.

-

Carcinogenicity

Chloroform has been classified as a probable human carcinogen by the International Agency for Research on Cancer (IARC). Studies have shown an increased risk of certain types of cancer, including kidney cancer, in individuals exposed to high levels of chloroform.

-

Environmental Impact

Chloroform’s toxicity extends beyond human health. It can be harmful to aquatic organisms and can contribute to air and water pollution. Proper disposal methods are crucial to minimize environmental contamination.

Understanding the toxicity of chloroform is paramount for those involved in its synthesis or handling. Implementing strict safety protocols, using appropriate personal protective equipment, and adhering to regulatory guidelines are essential to prevent adverse health effects and environmental harm.

Regulation

The regulation of chloroform is intricately connected to “how to make chloroform” due to its inherent toxicity. Understanding the regulatory landscape is crucial for ensuring responsible synthesis, handling, and disposal of chloroform.

-

Licensing and Permits

In many countries, the production, sale, and use of chloroform are subject to licensing and permit requirements. These regulations aim to control the distribution and use of chloroform, ensuring that it is handled only by qualified individuals and organizations.

-

Manufacturing Standards

Regulatory bodies establish strict manufacturing standards for chloroform to ensure its purity and minimize the risk of contamination. These standards govern the production process, equipment, and quality control measures.

-

Safe Handling and Storage

Regulations also mandate proper handling and storage practices for chloroform. This includes guidelines for appropriate personal protective equipment, ventilation, and storage facilities to prevent accidental exposure or release into the environment.

-

Disposal and Waste Management

Due to its hazardous nature, chloroform disposal is heavily regulated. Specific protocols must be followed to ensure that chloroform waste is treated and disposed of safely, minimizing environmental impact and protecting public health.

Understanding and adhering to these regulations are essential for responsible handling of chloroform throughout its lifecycle, from synthesis to disposal. By implementing these measures, we can mitigate the risks associated with chloroform and ensure its safe and controlled use.

FAQs

This section addresses frequently asked questions regarding the synthesis and handling of chloroform, providing concise and informative answers.

Question 1: Is it legal to make chloroform?

Answer: The legality of chloroform synthesis varies depending on the country and jurisdiction. In many regions, the production, sale, and use of chloroform are strictly regulated due to its toxic nature. It is essential to consult local laws and regulations before attempting to synthesize chloroform.

Question 2: What are the dangers of chloroform?

Answer: Chloroform is a highly toxic substance. Exposure to high concentrations can cause dizziness, nausea, and even death. Prolonged exposure can lead to liver and kidney damage, and it is classified as a probable human carcinogen. Proper safety measures, including adequate ventilation and personal protective equipment, are crucial when working with chloroform.

Question 3: What is chloroform used for?

Answer: Historically, chloroform was used as an anesthetic and antiseptic. However, due to its toxicity, it is no longer commonly used in medical settings. Today, chloroform finds limited use in industrial applications, such as the production of dyes and rubber.

Question 4: How is chloroform made?

Answer: Chloroform can be synthesized through various methods, including the reaction of chlorine and methane in the presence of a catalyst. This process requires specialized equipment and expertise and should only be attempted by qualified professionals in a controlled laboratory setting.

Question 5: How do you dispose of chloroform safely?

Answer: Due to its hazardous nature, chloroform must be disposed of properly to minimize environmental impact. Specific protocols and regulations vary depending on the jurisdiction. In general, chloroform waste should be treated and disposed of by licensed waste management companies.

Question 6: What are the alternatives to chloroform?

Answer: Safer alternatives to chloroform exist for both medical and industrial applications. In surgery, modern anesthetics with improved safety profiles are used. In industry, less toxic solvents and chemicals have replaced chloroform in many applications.

Understanding these FAQs provides valuable insights into the dangers, regulations, and responsible handling of chloroform. It is crucial to approach chloroform synthesis and use with utmost caution and adhere to established safety protocols to prevent accidents and protect human health and the environment.

Transition to the next article section: Understanding the Properties and Applications of Chloroform

Cautions Regarding Chloroform Synthesis

Chloroform synthesis involves hazardous chemicals and specialized techniques. It is crucial to exercise extreme caution and follow strict safety protocols to minimize risks.

Tip 1: Obtain Proper Training and Supervision

Chloroform synthesis should only be attempted by qualified professionals who have received proper training and are working under the supervision of an experienced chemist.

Tip 2: Use Appropriate Equipment and Facilities

Ensure access to a well-equipped laboratory with adequate ventilation, personal protective equipment, and emergency response measures in place.

Tip 3: Adhere to Safety Protocols

Strictly follow established safety protocols, including wearing appropriate protective gear, maintaining a clean work area, and handling chemicals with care.

Tip 4: Avoid Inhalation and Skin Contact

Chloroform vapors and liquid can be harmful upon inhalation and contact with skin. Use proper ventilation and wear gloves, protective clothing, and a respirator to prevent exposure.

Tip 5: Store and Dispose of Chloroform Safely

Store chloroform in tightly sealed containers in a cool, well-ventilated area. Dispose of chloroform waste according to local regulations and through licensed waste management companies.

Tip 6: Be Aware of Legal Implications

The production, sale, and use of chloroform are heavily regulated in many jurisdictions. Familiarize yourself with local laws and obtain necessary permits before attempting synthesis.

Tip 7: Consider Alternative Methods

Explore alternative methods or commercially available sources of chloroform if possible. This can help minimize the risks associated with synthesis.

Tip 8: Prioritize Safety Above All

Remember that safety should be the top priority throughout the chloroform synthesis process. Do not compromise on safety measures, and if any doubts arise, consult with experts or seek professional assistance.

By following these tips, individuals involved in chloroform synthesis can mitigate potential hazards and ensure a safe and responsible approach to this delicate procedure.

Transition to the article’s conclusion: Conclusion: The Importance of Responsible Chloroform Handling

Conclusion

The exploration of “how to make chloroform” has shed light on the complexities and potential hazards associated with this compound. Understanding the synthesis, properties, usage, toxicity, and regulations surrounding chloroform is crucial for responsible handling and minimizing risks.

While chloroform has historical significance, its toxicity and the availability of safer alternatives necessitate a cautious approach. Strict adherence to safety protocols, proper training, and legal compliance are essential to prevent accidents and protect human health and the environment. It is the responsibility of individuals involved in chloroform synthesis and use to prioritize safety above all else.

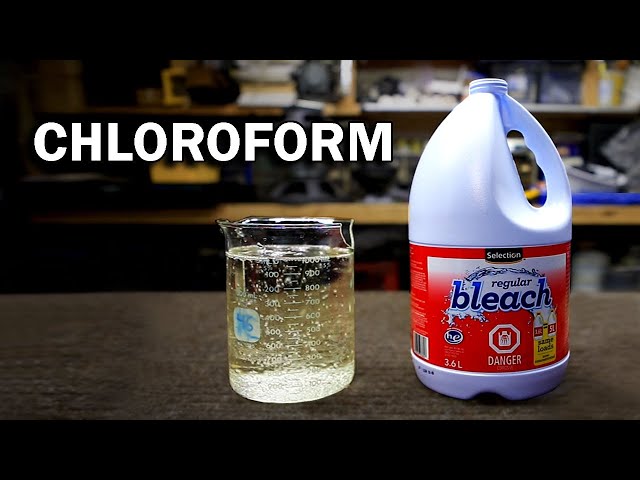

Youtube Video: